WheelsCLEAN™

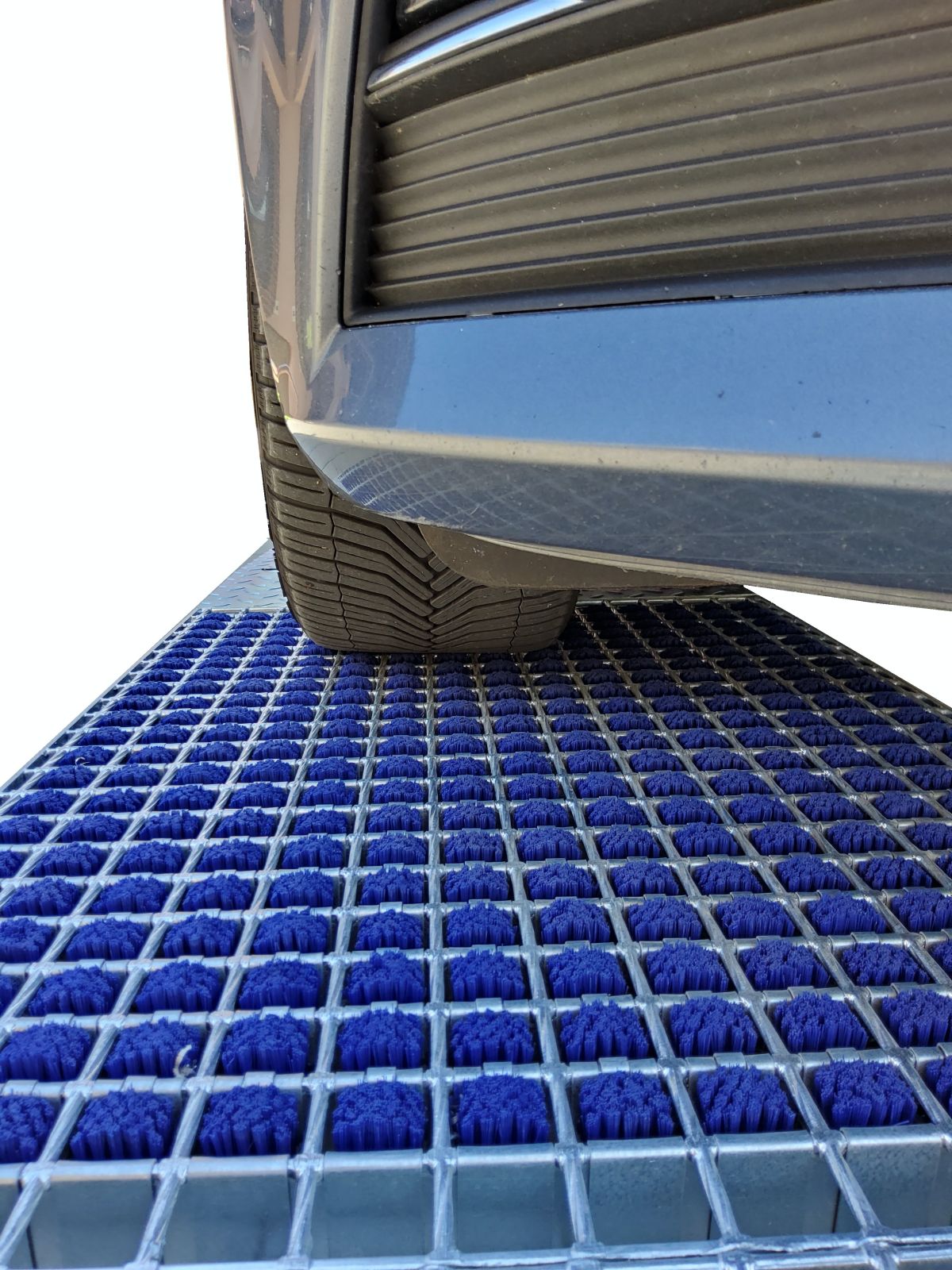

A system for cleaning the tread of tires,

wheels, rollers and shoes.

WheelsCLEAN™

Placing the system at strategi

With this solution, the cleani

*90% efficiency when driven th

APPLICATION OF WheelsCLEAN™

WheelsCLEAN™ SYSTEM IS ESPECCIALY USEFUL FOR INDUSTRIAL APPLICTIONS, WHEREVER:

- there is a lot of wheel traffic

- goods are moved from outside

to inside or between areas that require a high level of cleanliness (e.g. from workshop areas to production and storage areas) - there are high costs

associated with cleaning the s urface - purity affects the quality

of the final product - a dry surface should be prov

ided (braking distance on wet surfaces is much longer th an on dry surfaces, which incre ases the risk of collision and accidents, as wet, slippery floors have a negative effect on wheel adhesio n). - there is an increased risk

of bacteria being transmitted by vehicles and pedestrians - we want to protect the surfaces from s

cratches and extendtheir lifes pan - ISO 16232, VDA 19.1 standards and norms are r

equired - a production process improve

ment project (such as TPM) is implemented - BRCG standards are implement

ed - HACCP systems are implemented

Benefits of WheelsCLEAN™

- Clean entrances and traffic

routes mean clean production and higher quality indicators of products. - Less dirt increases the qual

ity of the working environment, reduces the risk of accidents such as slipping. - Lower cleaning costs by up

to 40%. - Replaceable brushes mean low

er costs associated with handling and cleaning. - The possibility of installat

ion on an existing facility does not require surface preparation. - Protection of exit and hall surfaces against damage.

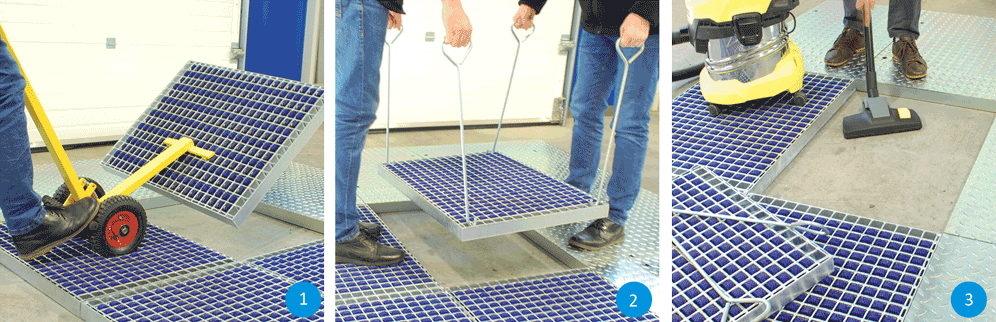

SYSTEM OPERATION

For the proper operation of the system it is recommended to systematically remove the accumulated dirt from under thegri

For this purpose, we use a special trolley (1) o

Move the grilles to the overla

We also clean the grating itse

Check the condition of the brushes and replace them if they are worn out.

The brushes are knocked out by a defocused rod and mountedinversely by pressing the brush into the

SERVICE AND MAINTENANCE

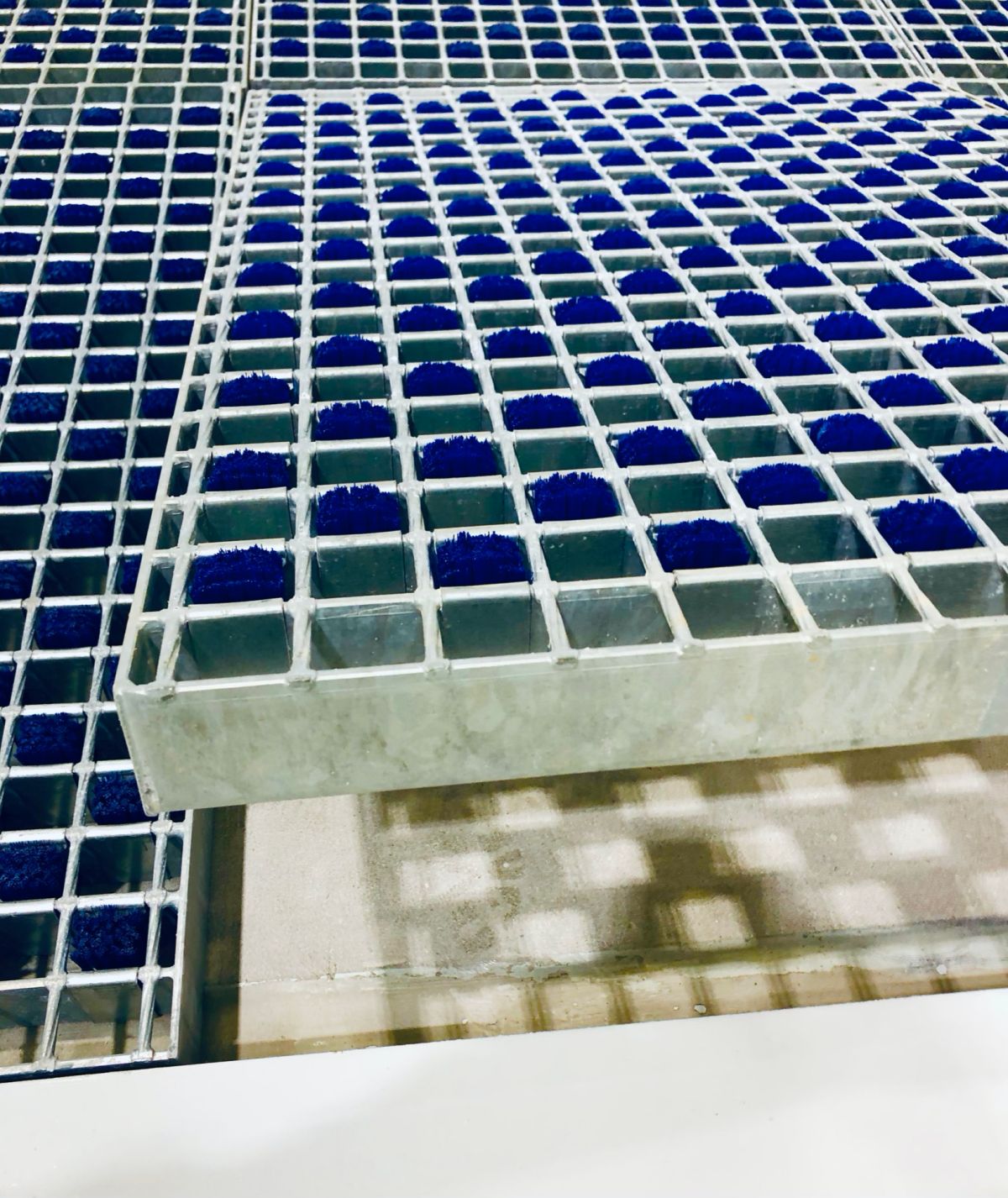

TECHNICAL SPECIFICATIONS

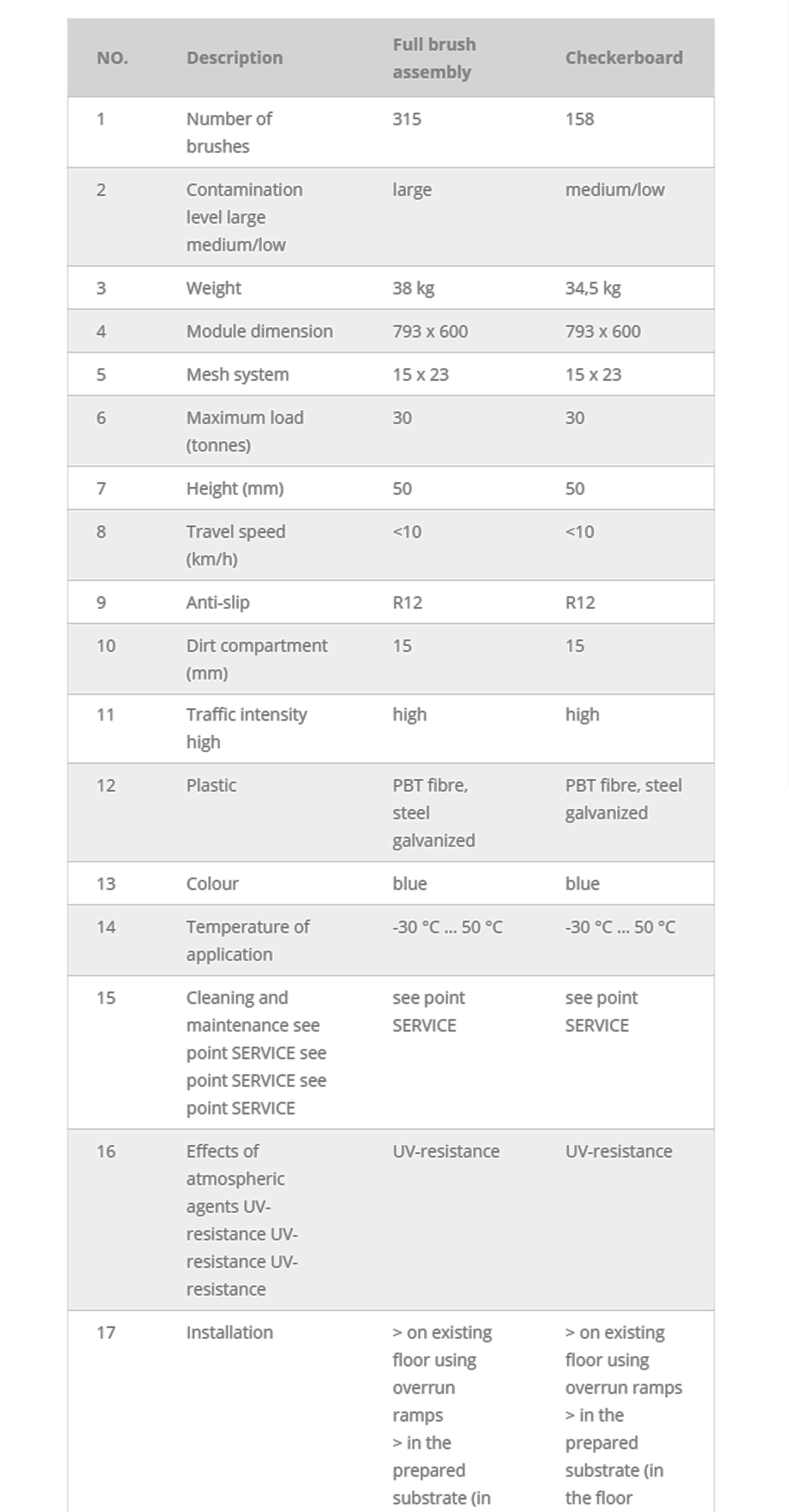

| NO. | Description | Full brush assembly | Checkerboard |

|---|---|---|---|

| 1 | Number of brushes | 315 | 158 |

| 2 | Contamination level large medium/low | large | medium/low |

| 3 | Weight | 38 kg | 34,5 kg |

| 4 | Module dimension | 793 x 600 | 793 x 600 |

| 5 | Mesh system | 15 x 23 | 15 x 23 |

| 6 | Maximum load (tonnes) | 30 | 30 |

| 7 | Height (mm) | 50 | 50 |

| 8 | Travel speed (km/h) | <10 | <10 |

| 9 | Anti-slip | R12 | R12 |

| 10 | Dirt compartment (mm) | 15 | 15 |

| 11 | Traffic intensity high | high | high |

| 12 | Plastic | PBT fibre, steel galvanized | PBT fibre, steel galvanized |

| 13 | Colour | blue | blue |

| 14 | Temperature of application | -30 °C … 50 °C | -30 °C … 50 °C |

| 15 | Cleaning and maintenance see point SERVICE see point SERVICE see point SERVICE | see point SERVICE | see point SERVICE |

| 16 | Effects of atmospheric agents UV-resistance UV-resistance UV-resistance | UV-resistance | UV-resistance |

| 17 | Installation | > on existing floor using overrun ramps > in the prepared substrate (in the floor surface with surface frame) | > on existing floor using overrun ramps > in the prepared substrate (in the floor surface with surface frame) |

| 18 | Place of application | > outside the building > inside the building | > outside the building > inside the building |

WheelsCLEAN™

Phone number

+48 607 626 942

Headquarters

ul. Ogrodowa 26,

42-713 Kochcice